THE FUTURE OF PORT LOGISTICS

Authors

Pavlikhin Andrey

Share

Annotation

The article explores the key trends in digital transformation and automation of port logistics within the context of global and national sustainable development strategies. It examines modern models for integrating port management information systems and technologies that enhance productivity and environmental efficiency at terminals. Special attention is given to the role of Automated Guided Vehicles (AGVs) as a core element of technological modernization in ports. It is demonstrated that the combination of AGVs, Just-In-Time synchronization, Digital Twin technology, and robotics in STS cranes creates a new level of operational efficiency in ports. The article also analyzes the regulatory and environmental requirements set by IMO and the EU for the transition to smart and green ports. Predictive scenarios for phased automation in Russian ports are presented, and the prospects for implementing these solutions in the Black Sea and Baltic regions are outlined.

Keywords

Authors

Pavlikhin Andrey

Share

Introduction

Global maritime trade and port logistics continue to be fundamental components of global supply chains, accounting for more than 80% of international trade in goods. According to the United Nations Conference on Trade and Development (UNCTAD), in 2023, maritime trade volume increased by 2.4%, despite geopolitical uncertainties and the impact of the pandemic. The total port logistics market reached approximately $371 billion, demonstrating steady growth, with a forecast compound annual growth rate (CAGR) of about 3.9% by 2032 [5].

In today's environment, digitalization and automation of port operations are becoming a top priority. The increasing volume of container traffic has led to a need for a shift from manual operations to autonomous systems that can ensure continuous operation and high levels of accuracy. One such solution is the use of AGV (automated guided vehicles), which are electric self-propelled platforms that move containers horizontally between the dock and the back areas of the terminal. These vehicles can reduce operating costs and eliminate the impact of human error, while also reducing local emissions to zero.

The development of the smart port concept involves integrating automated guided vehicles (AGVs) into a single digital system that combines terminal management systems (TMS) and port community system (PCS). This integration, combined with the principles of just-in-time (JIT) scheduling and digital twin technologies, ensures the synchronization of ship arrivals, optimization of energy use, and increased port capacity. As a result, automation not only enhances efficiency but also contributes to environmental and energy sustainability.

This study aims to identify key trends and scenarios in the development of port logistics through digital transformation, explore the role of AGVs in shaping a smart, environmentally friendly port architecture, and assess the potential for their implementation in Russian ports in the Black Sea and Baltic regions.

Theoretical foundations of port logistics

Port logistics is a complex system of organizational, technical, informational, and legal processes that facilitate the movement of goods, ships, and vehicles through seaports as key nodes in global supply chains. Modern logistics theory views ports not only as transshipment points but also as integration platforms that bring together shipping lines, terminals, customs services, freight forwarders, and transport corridors in a unified digital ecosystem. The effectiveness of this system relies heavily on the level of digitalization, standardization of data exchange, and automation of processes. By leveraging technology, ports can optimize operations, reduce costs, and improve efficiency, ultimately contributing to the overall success of the supply chain.

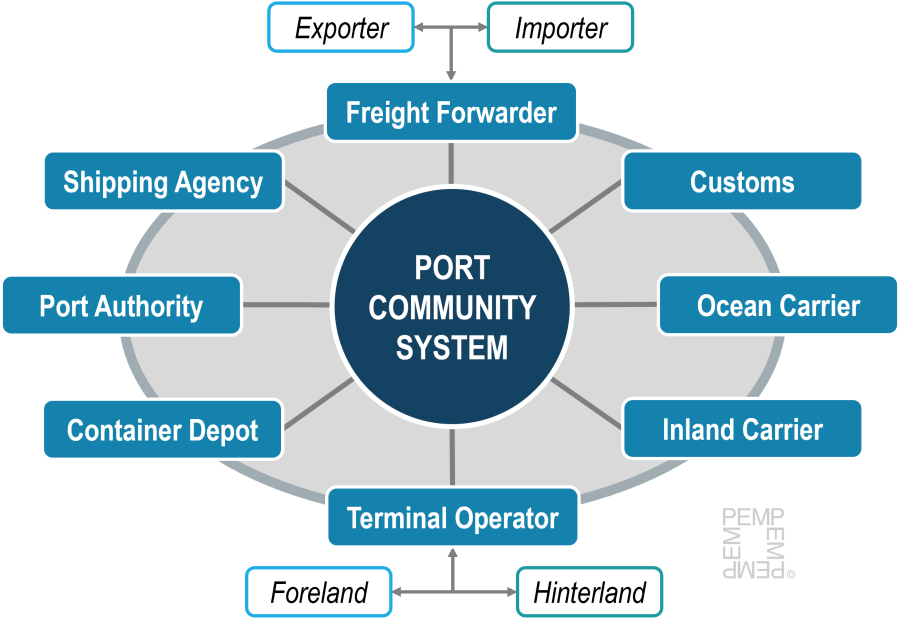

The key element of the port's digital ecosystem is the Port Community System (PCS), an open and neutral electronic platform that brings together public and private stakeholders in the port (including administrations, terminals, shipping lines, forwarders, and customs) to facilitate intelligent and secure data exchange. The platform operates on the principle of "single entry - multiple use", allowing users to access and share information in a secure and efficient manner. The figure below illustrates the architecture of the port community and the Port Community System, which brings together all key participants in the logistics chain, including port authorities, terminal operators, shipping lines, freight forwarders, and customs.

Fig. The structure of interaction of participants in the Port Community System [6]

In the smart port operating architecture, a bundle of PCS–TMS, AGV, and STS forms a cyber-physical system. PCS and TMS coordinate tasks, while AGVs provide autonomous horizontal movements of containers, and STS cranes perform vertical operations. At the current level of development, STS cranes are often the "bottleneck" because they require the participation of a human operator. The next step is to automate them in a single control loop, which will reduce the need for human intervention.

From the point of view of comparative assessment and benchmarking, two indices are used: the LSCI (Line Shipping Connectivity Index) from UNCTAD and the CPPI (Container Port Performance Index). The LSCI measures a country or port's "embeddedness" in the liner-shipping network, taking into account factors such as frequency, vessel capacity, and number of services. The CPPI, on the other hand, measures the efficiency of ports based on ship time in port and processing performance. In 2023, countries with the highest connectivity according to the LSCI included China, the Republic of Korea, Singapore, Malaysia, and the United States. These countries demonstrate a concentration of capacity and network effects in their East and Southeast Asian hubs, as well as North American hubs, according to this index [4].

Current trends and technologies in port logistics

Modern port logistics are undergoing a significant technological transformation, driven by the shift from disparate information technology (IT) solutions to integrated, digital smart port ecosystems. This transformation is being driven by the automation of overloading operations, predictive analytics, data integration, and the implementation of cyber-physical management models. Digitalization is becoming essential for the sustainability and competitiveness of ports, as it helps them adapt to global trade volatility and increasingly stringent environmental regulations.

The technological vector is shaped by three interconnected areas: first, the complete or partial automation of terminals, including electrified automatic gantry cranes and autonomous AGV vehicles, as well as remote control of transshipment equipment. Second, the introduction of tools for synchronizing ship loading and predictive analytics, such as ETA/ETD. Third, the creation of digital replicas of the port's infrastructure and operations, which optimize mooring, towing, berth planning, and rear-area processing.

The most significant example of the integration of these technologies is Tuas Port in Singapore, the world's largest fully automated terminal, which operates hundreds of electrified AGVs and automated cranes with centralized control from a single digital center. The system provides round-the-clock operation, reduces greenhouse gas emissions by almost 50% compared to its diesel counterparts, and creates new high-tech jobs. The project is being implemented under the management of PSA Singapore in cooperation with the A*STAR research agency, where AGV flotilla coordination algorithms based on high-performance computing have been developed [3].

In Europe, the port of Rotterdam, where the PortXchange platform operates, serves as an example of the implementation of digital management tools. This platform provides real-time data exchange between shipping lines, terminals, and port services, allowing for the synchronization of ship arrivals and operations at berths based on the Just-in-Time Arrival principle. This approach helps reduce downtime, fuel consumption, and improves the accuracy of port resource planning. Combined with digital counterparts, the Port Authority of Rotterdam has created a "forecasting management" model where all participants operate in a unified information space.

Table 1 presents the key technological trends in port logistics along with verifiable examples.

Table 1 – Key technological trends in port logistics and verifiable examples

|

The trend |

Content / effect |

Examples |

|

Automation of port terminals |

The introduction of automatic cranes, autonomous vehicles (AGVs), and digital warehouse management systems increases productivity and reduces the impact of human error. |

In 2023, the largest automated terminal in the world with electrified automated guided vehicles (AGVs) and remotely operated cranes, PSA Singapore, is operating at the Tuas Port in Singapore. |

|

Synchronization of ship arrivals (Just-in-Time Arrival) |

Using digital platforms to coordinate ships, terminals, and services, we can reduce downtime and fuel consumption. |

PortXchange (Rotterdam, Hamburg) is a platform for exchanging ETA/ETD data in real time, integrated with AIS and port systems |

|

Digital port twins |

Real-time modeling of port infrastructure and data flows, as well as forecasting berth loading, towing, and transshipment operations. |

The Port of Rotterdam Digital Twin is a system that visualizes the water area, depth, traffic, and weather data. It is used to optimize shipping schedules and calls. |

|

Internet of Things (IoT) and Predictive Analytics |

Monitoring of equipment and cargo using sensors; analysis of data to prevent downtime and optimize routes. |

The Hamburg Port Authority has introduced the SmartPort Logistics platform, which uses IoT (Internet of Things) devices and analytics to manage traffic and ships. |

|

Artificial intelligence and machine learning |

They are used for estimating the expected time of arrival (ETA), planning crane operations, analyzing container flow, and monitoring energy consumption. |

DP World has implemented AI systems at its Jebel Ali and London Gateway terminals, and in Singapore, PSA Marine is using ML algorithms to optimize tugboat operations. |

|

Blockchain and electronic documents |

Ensuring transparency and security in supply chains, and reducing the time of customs procedures. |

TradeLens (IBM + Maersk) and CargoSmart are used in Asia and Europe to facilitate document exchange between shipping lines and port authorities. |

|

Environmental Technologies (Green Ports) |

Electrification of equipment, use of renewable energy sources, and coastal power supply for ships (OPS). |

The ports of Los Angeles and Gothenburg have installed OPS systems to reduce CO₂ emissions from ships when they are in port. |

|

Port Community System (PCS) Integration |

A centralized digital platform for all participants in the logistics chain, including customs, terminals, agents and carriers. |

In 2023, PCS systems will be fully implemented at the Antwerp-Bruges, Rotterdam, and Valencia port complexes. These systems will provide the exchange of more than 20 million messages per day. |

Source: author's development.

AGVs have already demonstrated positive effects in container terminals in various countries, including increased processing speed, reduced operational costs and injuries, and improved environmental performance. A comparison between a port without an AGV system and a port equipped with AGVs is presented below, highlighting key economic and operational indicators (Table 2).

Table 2 – Comparative characteristics of ports without AGV and with AGV

|

Indicator |

Port without AGV |

Port with AGV |

|

Organization of work |

Manual control, human factor in planning and executing operations. |

Fully automated ground logistics management via TMS/PCS in 24/7 mode, without shifts or downtime. |

|

Capital expenditures (CAPEX) |

Low initial investment in machinery and infrastructure. |

High investments (tens of millions of dollars per terminal) are made in electric platforms and IT infrastructure. |

|

Operating costs (OPEX) |

High fuel, repair, and personnel costs. |

Reduction of operating costs by 20-30% through the use of electric traction and minimization of staffing. |

|

Efficiency |

Shift work, high dependence on personnel and weather conditions |

Increased container handling speed by 15-25%, 24/7 steady operation. |

|

Safety |

Risks of incidents and human error |

Reduced injuries and errors thanks to autonomous movement and sensory control. |

|

Environmental friendliness |

Internal combustion engine use, high noise and emissions (Noₓ, PM) |

Electric drive – zero local emissions, reduced noise and vibration. |

|

Flexibility and adaptability |

The possibility of operational decisions by the operator, but low predictability of the system |

High predictability and accuracy in tasks, with limited room for improvisation. |

|

Image and compliance with environmental standards |

Limited IMO and ESG compliance |

"Green" image and compliance with environmental initiatives, as well as IMO-2030 requirements. |

|

Return on investment |

Slow efficiency improvement with rising costs |

The average payback period for this investment is 3-5 years, thanks to the savings and increased efficiency it brings. |

Source: author's development.

The transition of global port logistics towards sustainable development is closely linked to the increasing international environmental regulations and the introduction of energy efficiency standards. Since January 1, 2023, the International Maritime Organization (IMO) has implemented mandatory indicators, EEXI (Energy Efficiency Existing Ship Index) and CII (Carbon Intensity Indicator), to reduce the carbon footprint of ships. These measures encourage shipping companies and ports to optimize shipping speeds, plan ship calls digitally, and improve infrastructure efficiency. Ports that integrate digital control systems and automated technologies gain a competitive advantage by accurately calculating energy use and predicting mooring windows with greater precision.

The European Union has introduced the FuelEU Maritime Regulation and the Fit for 55/AFIR block of measures, which require the mandatory use of onshore power supply for certain types of ships by 2030. These measures also include the development of standardized electrical infrastructure in ports of the TEN-T network. These initiatives aim to promote the transition to green technologies and require ports to install energy-monitoring systems and implement intelligent load management and power redundancy measures [2].

The practice of terminal automation has been confirmed by industry research, which has identified semi-automated and fully automated systems. Semi-automated systems involve human control of horizontal logistics and automated warehousing, while fully automated systems perform both horizontal movements and vertical processing without human intervention.

These systems are being implemented on a large scale in Asia and several European hubs, and are linked to increasing demands for the integration of transportation management systems (TMS), shift planning systems, and cybersecurity measures. Systematic reviews have identified significant benefits in terms of security and operational stability, but also emphasize the need for process redesign and staff training to ensure successful implementation [1].

Environmental and sustainable aspects of port logistics development

The transition of port logistics towards sustainable development has become a priority for the global transport industry. The main directions of environmental transformation in port logistics are:

- Onshore Power Supply (OPS) - connecting ships to electricity in the port to reduce CO2 and NOx emissions. By 2023, this system will be implemented at ports in Los Angeles, Gothenburg, Rotterdam, and Hamburg.

- Electric AGVs - as part of a "zero-emissions" fleet, they can reduce noise pollution and eliminate local NOx/PM emissions, which is important for ports located in urban areas.

- Alternative fuels - the use of LNG (liquefied natural gas), biofuels, hydrogen, and ammonia for port equipment and ships.

- IMO EEXI and CII - regulations for energy efficiency and the carbon index of ships that affect port schedules.

- Digital energy management - implementation of systems for monitoring and optimizing the use of electricity and terminal resources.

- Development of green shipping corridors - creation of international routes with minimal emissions (Clydebank Declaration initiative).

- Recycling and zero waste - recycling and reuse of packaging and construction materials in ports.

- Green certificates and ESG reporting - transition of port operators to sustainable development reporting standards (GRI, ESG index).

- Cooperation with city authorities - integration of ports into urban environmental infrastructure (wastewater treatment systems, noise reduction, greening of coastal areas).

These measures form the foundation for the transition of the global port system from a "growth-driven" model to a "sustainable and digital development" model. In this new model, efficiency is measured not only by the volume of cargo handled, but also by how well the infrastructure reduces its carbon footprint and promotes sustainability.

Geo-economic and political factors of the future of port logistics

Modern port logistics operate in a highly turbulent global economic environment, which directly impacts the strategies for technological renewal. The increased sanctions policy, fluctuations in currency values, rising energy costs, and disruptions to international supply chains all require ports to reconsider their development priorities. Intangible risks, such as cyber threats, also play a significant role, as they can destabilize operational processes and lead to temporary infrastructure blockages. Against this backdrop, the policies of technological sovereignty, digital security, and localization of critical components are becoming increasingly important. Investments in automation and digitalization are not just tools for optimization, but mechanisms for protecting against external risks. The use of autonomous vehicles (AGVs) integrated into port management systems (TMS and PCS) minimizes dependence on human factors, increases the stability of logistics operations, and ensures the predictability of cargo flows, even under external shocks.

For the ports of the Black Sea region, it would be beneficial to consider introducing AGVs as a key part of the modernization of land transportation systems in order to reduce costs, increase resistance to peak loads, and ensure the continuity of the transportation process. The most important factors for the successful implementation of such projects include access to qualified technical support, the establishment of reliable supply chains, and the gradual localisation of production and maintenance of equipment.

Forecast scenarios and directions of port logistics development

The basic scenario for the development of port logistics in the coming years involves a phased approach to automation. At the first stage, autonomous AGV (automated guided vehicle) vehicles will be introduced and land logistics will be digitalized. At the second stage, STS (ship-handling) cranes will be automated within a single TMS (terminal management system) control loop.

This sequence ensures a balance between technological risks and investment opportunities, as well as the rate of return on capital investments. In combination with JIT (just-in-time) synchronization mechanisms and digital twins, port systems can form predictable arrival windows, optimize operation planning, and create smoother energy consumption profiles at terminals. This, in turn, helps reduce operational peaks, improve resource utilization, and enhance the overall sustainability of infrastructure.

Further development of automation in ports involves integrating AGV (Automated Guided Vehicles), STS (Ship-to-Shore) systems, and intelligent control systems into a unified cyber-physical ecosystem. Algorithmic control of data and energy flow is a key factor in ensuring efficiency. The transition to this model will allow ports to adapt to increasing cargo volumes, environmental reporting requirements, and the need for global competitiveness.

Automation technology is still in its early stages in Russian ports, but there is significant potential for development. The Black Sea and Baltic regions are promising areas for pilot projects, as they have high cargo turnover and large terminals. These areas can serve as a testing ground for AGV and digital TMS/PCS (Terminal Management System/Process Control System) systems.

The use of autonomous electric platforms can increase the stability of ground logistics, reduce operating costs, and ensure compliance with environmental standards, without the need for major infrastructure reconstruction. The localization of equipment production, the training of engineering personnel, and the development of service support all play an important role in implementing such projects.

Challenges and barriers to innovation

The main obstacles to digitalization remain high costs, the fragmentation of information systems, and a lack of skilled IT personnel. Lack of trust between logistics chain participants and lack of uniform data exchange standards hinder integration. Additionally, for many ports, innovation can be economically risky due to long payback periods. These challenges can be addressed through public-private partnerships, standardization, and vocational education development.

Conclusion

Port logistics is undergoing a period of significant structural transformation due to the combined impact of technological, environmental, and geo-economic factors. As global practice confirms, digitalization and automation have become essential components for the competitiveness of modern ports.

One of the key directions of development is the gradual automation of operations. This includes the introduction of autonomous electric automated guided vehicles (AGVs) to optimize ground transportation, followed by the robotization of ship-to-shore (STS) cranes, creating a fully automated "side-to-warehouse" process. When combined with Just-in-Time (JIT) and Digital Twin technologies, this forms the basis for a cyber-physical system of a smart port where all processes can be managed in a unified digital space.

IMO and EU regulatory initiatives aimed at improving energy efficiency and reducing emissions are driving the electrification and digitalization of port infrastructure. These initiatives include the use of AGVs (autonomous ground vehicles) and intelligent energy management systems, which make it possible to combine economic efficiency with environmental sustainability.

Russia has identified the development of automated terminals as a strategic priority. Pilot projects based on AGVs and TMS/PCS (transportation and traffic management systems) digital platforms in the Black Sea and Baltic Sea ports can serve as a basis for establishing national standards for smart and green ports that can integrate into international digital logistics networks.

References:

Container Terminal Automation [Electronic resource]. – Access mode: https://metrans.org/assets/research/container%20terrminals%20automation-final%20report-for%20metrans%20posting.pdf.

EEXI and CII - ship carbon intensity and rating system [Electronic resource]. – Access mode: https://www.imo.org/en/mediacentre/hottopics/pages/eexi-cii-faq.aspx.

Maritime & Port Authority of Singapore (MPA) [Electronic resource]. – Access mode: https://www.mpa.gov.sg/home.

Maritime transport indicators [Electronic resource]. – Access mode: https://unctad.org/s ystem/files/official-document/rmt2023ch4_en.pdf .

Port Logistics Market Report | Global Forecast From 2025 To 2033 [Electronic resource]. – Access mode: https://dataintelo.com/report/global-port-logistics-mark.

Port Community System | Port Economics, Management and Policy [Electronic resource]. – Access mode: https://porteconomicsmanagement.org/pemp/contents/part3/digital-transformation/port-community-system/.

Review of Maritime Transport 2023 | UN Trade and Development (UNCTAD) [Electronic resource]. – Access mode: https://unctad.org/publication/review-maritime-transport-2023.