Optimization of industrial adiabatic cooling systems to reduce energy consumption and carbon dioxide emissions

Authors

Nikitin Vitaly Vyacheslavich

Share

Annotation

The article discusses the urgent task of improving the energy and environmental performance of industrial facilities through the optimization of adiabatic cooling systems. It analyzes the basic principles of adiabatic system operation and their advantages over traditional compressor units. The focus is on the development and analysis of optimization techniques aimed at achieving a balance between maximum cooling capacity, minimal water consumption, and, consequently, reduced electricity usage. The paper presents mathematical models and control algorithms that allow the system to adapt to changing climate conditions and thermal loads in real-time. It also justifies the direct link between reduced energy consumption and reduced indirect carbon dioxide (CO2) emissions associated with electricity generation. The results of the study show that the introduction of intelligent adiabatic cooling systems can significantly reduce the operating costs and carbon footprint of industrial facilities and data centers

Keywords

Authors

Nikitin Vitaly Vyacheslavich

Share

The relevance of research. Modern industrial enterprises are striving to reduce the energy intensity and environmental impact of their production processes. Adiabatic cooling systems, used for air conditioning in process rooms and equipment, represent an energy-efficient alternative to traditional compression systems. However, the use of these systems can sometimes lead to the irrational use of water and energy resources.

Optimizing these systems can significantly reduce electricity consumption and direct and indirect CO2 emissions, in line with global trends towards sustainable development and international energy efficiency standards.

The purpose of the study. The main goal of the research is to develop and scientifically justify a methodology for optimizing industrial adiabatic cooling systems, aiming to simultaneously reduce electricity consumption and indirect carbon dioxide emissions while maintaining the necessary cooling capacity.

To achieve this goal, a number of tasks must be completed. First, existing systems must be analyzed to identify key performance indicators. Then, a mathematical model must be developed to describe the thermodynamic, energy, and water processes within the system. Based on this model, a multi-criteria optimization algorithm must be created that can find the best balance between cooling efficiency, water use, and energy use in real time. Finally, the system's performance must be simulated numerically for various conditions, and the potential for energy savings and CO2 reductions compared to traditional or unoptimized systems must be quantified.

Materials and methods of research. The current industrial adiabatic cooling systems used in the food, chemical, and metallurgical industries are the focus of this research. During the study, methods of thermodynamic analysis, energy and exergy balances, mathematical modeling of mass and heat transfer processes, as well as computer simulation tools such as CFD modeling, are employed.

The experimental component involves collecting data on actual operating conditions of the equipment, measuring temperatures, humidity, airflow, and water flow. To evaluate the environmental impact, a method for calculating the carbon footprint is used, based on CO2 emission factors calculated from electricity consumption. Based on the collected data, recommendations are developed for technological and design improvements aimed at enhancing the energy efficiency of these systems.

The results of the study. The idea of adiabatic cooling, which is based on using water evaporation to reduce air temperature, dates back to ancient times. In ancient Egypt and Persia, simple evaporation devices such as vessels with a porous surface were used, through which air passed and was cooled by the evaporation of moisture. This principle was also applied in architecture, with wind towers and fountain systems creating natural cooling for rooms.

Since the early XX century, as industry developed and the need for air conditioning increased, adiabatic systems began to receive engineering attention. The first industrial installations, used in textile and food manufacturing, employed direct water evaporation in air streams. However, these systems were limited by climate conditions, so further development focused on improving control over heat and mass transfer processes.

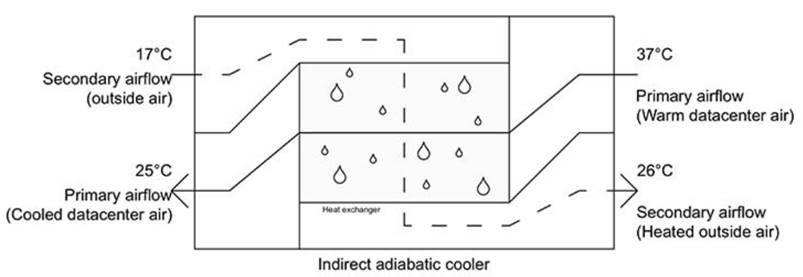

In the second half of the XX century, new indirect adiabatic cooling systems were developed, which did not require water to enter the working airflow. Instead, cooling occurred through heat exchange surfaces, making it possible to use these systems over a wider range of temperatures and humidities, including areas with high relative humidity. (Fig. 1)

Fig. 1 – Indirect adiabatic cooling scheme

Since the 1980s and 1990s, computer technology has played a significant role in the design of more efficient adiabatic systems using computational fluid dynamics (CFD) techniques. During this time, combined systems that combine adiabatic cooling with mechanical cooling or heat recovery have emerged, increasing their overall energy efficiency [2].

In the XXI century, researchers and industry have focused on increasing environmental sustainability and reducing energy consumption. This has led to the introduction of intelligent control systems and automatic water and air flow optimization, which have significantly reduced operating costs and the carbon footprint.

Modern adiabatic systems, such as those used in data centers and logistics complexes, are an integral part of the "smart" and energy-efficient industry. These systems have evolved from simple evaporative technologies to more complex, integrated solutions that meet today's environmental and energy-saving standards (Tab. 1).

Table 1 – Evolution of adiabatic cooling systems

|

№ |

Name |

Characteristic |

|

1 |

Traditional technologies |

In the early days, simple methods such as fans and natural convection were used to cool the air. However, these systems were not very effective and consumed a significant amount of energy. |

|

2 |

Use of water |

The introduction of water-cooling, where water is evaporated to lower air temperature, has significantly increased efficiency. However, this process requires a significant amount of water. |

|

3 |

Adiabatic coolers |

The development of adiabatic coolers, which use the principle of evaporative cooling, has led to a reduction in energy consumption and an increase in efficiency. |

|

4 |

Modern technologies |

The introduction of microcontrollers and sensors has allowed us to automate cooling processes and make them more adaptable to environmental conditions. |

|

5 |

New materials |

The use of modern thermal insulation and water-resistant materials to enhance the efficiency of systems. |

|

6 |

Integration with sustainable energy sources |

Modern adiabatic systems are often combined with solar panels and other renewable energy sources, which makes them more environmentally friendly. |

|

7 |

Smart technologies |

Implementation of the IoT (Internet of Things) for monitoring and control of cooling systems, which allows optimizing their operation in real time. |

It should be noted that, in recent decades, the development of industrial adiabatic cooling systems has focused on improving energy efficiency and reducing environmental impact. Modern solutions incorporate automated control systems, innovative heat exchange materials, and a comprehensive analysis of air and moisture flow [1].

One of the key areas of focus is the use of intelligent control systems. These systems allow for real-time monitoring and control of water flow, fan speed, and incoming air temperature. By taking into account weather data, heat load, and indoor conditions, these systems can optimize water and energy consumption. Thanks to adaptive algorithms, electricity consumption can be reduced by 20-40%, compared to traditional systems. In addition, water consumption can also be optimized.

Another significant area is the development of hybrid adiabatic systems. These systems combine evaporative cooling with either mechanical (compressor) cooling or regenerative heat exchange, ensuring stable air parameters and minimal energy consumption. These hybrid schemes are particularly useful in data centers, where equipment temperature directly affects work efficiency. In some European data centers, the use of adiabatic cooling has resulted in a 30-50% reduction in carbon footprint compared to traditional air conditioning systems.

Innovative materials also play a significant role in this process. Modern evaporation units, made from cellulosic, nanostructured, or ceramic materials, offer a higher evaporation rate and reduce the risk of bacterial growth. This not only reduces maintenance costs but also increases the longevity of the equipment [3].

An important aspect of aerodynamics is digital modeling and optimization, which allows for the design of systems with minimal pressure loss and even airflow distribution. The use of computational fluid dynamics (CFD) models helps adjust the geometry of channels and nozzle placement, improving heat and mass transfer efficiency.

One promising solution is the recovery of moisture and energy through two-stage cooling systems and exhaust air recycling. These systems can reduce energy consumption by up to 60%, compared to traditional air conditioning units. These technologies are actively being implemented in logistics facilities, the food industry, and large-scale ventilation systems.

Optimization of industrial adiabatic cooling systems relies on digital technologies, intelligent controls, hybridization, and new high-performance materials. These technologies not only significantly reduce energy consumption but also contribute to reducing CO₂ emissions, promoting the development of a more sustainable and environmentally friendly industry.

Despite their energy efficiency and environmental advantages, modern industrial cooling systems face several challenges that limit their potential for optimization. The main challenge is the instability of performance depending on climatic conditions. During high humidity, water evaporation intensity decreases, leading to a reduction in cooling efficiency and a need for additional mechanical cooling. This increase in energy consumption indirectly increases carbon emissions.

Another significant issue is the high water consumption. Intense evaporation requires a substantial amount of liquid, particularly with high system efficiency. An inefficient water circuit and lack of a closed water loop increase resource scarcity and impact operational sustainability. Additionally, when salts and contaminants accumulate in the water, heat transfer decreases, and frequent cleaning or replacement of the evaporation panels becomes necessary.

The correct configuration of automated control systems can be difficult. To achieve maximum energy efficiency, a precise interaction between temperature, humidity, pressure sensors, and fan and pump controllers is necessary. Even small errors in the algorithms can lead to energy wastage or unstable microclimate parameters. Additionally, the introduction of intelligent systems requires capital investment and staff training, which can hinder the widespread adoption of innovation.

The reliability and durability of the components remain a significant challenge. Adiabatic cooling, while effective, is associated with high humidity, which can lead to corrosion of metal elements and reduce the service life of fans, pumps, and panels. This requires the use of expensive anti-corrosive materials and regular maintenance, which adds to the cost of the system.

Another issue is the lack of advanced digital modeling tools. Despite the availability of CFD (computational fluid dynamics) analysis systems, detailed simulations of evaporation and turbulent flow are not commonly used in practical applications. This can lead to design errors and unnecessary energy losses, as well as increased maintenance costs.

The main challenges in optimizing adiabatic cooling systems include climate-dependent efficiency, water scarcity, complex control, technical reliability, and insufficient digitalization in design. Addressing these issues requires an integrated approach that includes implementing intelligent monitoring systems, utilizing sustainable materials, establishing closed water supply cycles, and adapting technologies to regional climate conditions.

We believe that optimizing industrial adiabatic cooling systems requires a multi-layered process aimed at enhancing energy efficiency, minimizing water consumption, and ensuring reliable operation of equipment across diverse climates.

The basis of the modern approach is the integration of engineering solutions, automation, and digital control technologies. This involves adapting the operating modes of a system to changes in temperature and humidity using intelligent control algorithms. These algorithms regulate the speed of fan rotation, water spray intensity, and pump performance, based on machine learning principles. This allows the system to learn and predict future climate conditions, optimizing resource allocation for maximum efficiency.

A significant role is played by reducing water consumption with closed water circulation systems, filtration, and recirculation, which prevent excessive moisture loss. The building uses materials with increased corrosion resistance and hydrophilic coatings, which promote uniform evaporation and the durability of the building's elements.

CFD models and digital twins are used to improve the efficiency of airflow, allowing for the prediction of temperature and humidity distribution at all stages of design and operation. Automated monitoring systems connected to cloud platforms collect real-time data from temperature, humidity, and vibration sensors, enabling proactive maintenance and emergency prevention.

Energy saving is achieved through the introduction of frequency-controlled engines, optimization of duct aerodynamics, and the use of renewable energy sources. In the future, the development of these systems will involve the use of neural networks for integrated climate management, intelligent equipment diagnostics, and the complete digitalization of design and operational processes.

The detailed optimization of industrial adiabatic cooling systems ensures a high level of energy efficiency, environmental sustainability, and reliability at minimal operating costs.

Conclusion. Optimization of industrial adiabatic cooling systems is a crucial aspect in the development of modern energy-efficient technologies and the enhancement of environmental sustainability in production processes.

The use of intelligent control algorithms, digital twins, and automated monitoring ensures the flexibility and accuracy of equipment operation, while minimizing energy and water consumption. Increased efficiency is achieved through an integrated approach that includes engineering improvements to the design, optimization of aerodynamics, and the introduction of adjustable drives and recirculation systems.

Digitalization of the design and operation processes is essential, as it enhances transparency, predictability, and reliability of integrated systems. The development of adiabatic cooling helps reduce the carbon footprint by minimizing the impact on urban energy systems, while also increasing the competitiveness of businesses.

In the future, the integration of artificial intelligence, the Internet of Things, and sustainable engineering solutions will form the basis for establishing new standards in the field of industrial climate systems. These systems will ensure a balance between production efficiency and conservation of natural resources, leading to a more sustainable future.

References:

- Dolgov A.I., On the issue of optimizing gas turbine cooling systems // Technological audit and production reserves. – No. (1 (7)). – 2012. – pp. 7-8.

- Tarabarin L.I. Optimization of the exhaust gas treatment plant of industrial and energy enterprises from harmful emissions, including greenhouse gases // Innovations and investments. – No. (10). – 2023. – pp. 188-192.

Yang Yu., Chen S.-S. Thermodynamic modeling of CO2 solubility in aqueous solutions of NaCl and Na2SO4 // Investigation of supercritical fluids. - 2010. – No. 55. – pp. 623-634